ANEST IWATA MOTHERSON LTD. is a joint venture between Anest Iwata, Japan, a world technology leader in oil free and lubricated compressors since 1928 and Sumi Motherson Group, an Indian conglomerate with presence in various sectors. These Compressors are being manufactured as per JIS standard in a state of the art plant in India and complete know how for design & manufacturing of the compressors is being provided by ANEST IWATA CORPORATION – JAPAN.

As a patented technology of Anest Iwata, Japan, it brings in absolute ruggedness and reliability to run smoothly for years and years. Our unbeatable design provides you remarkable advantages over traditional design compressors. Some of the major benefits of our revolutionary Quadra Edge™ technology can be listed as below…

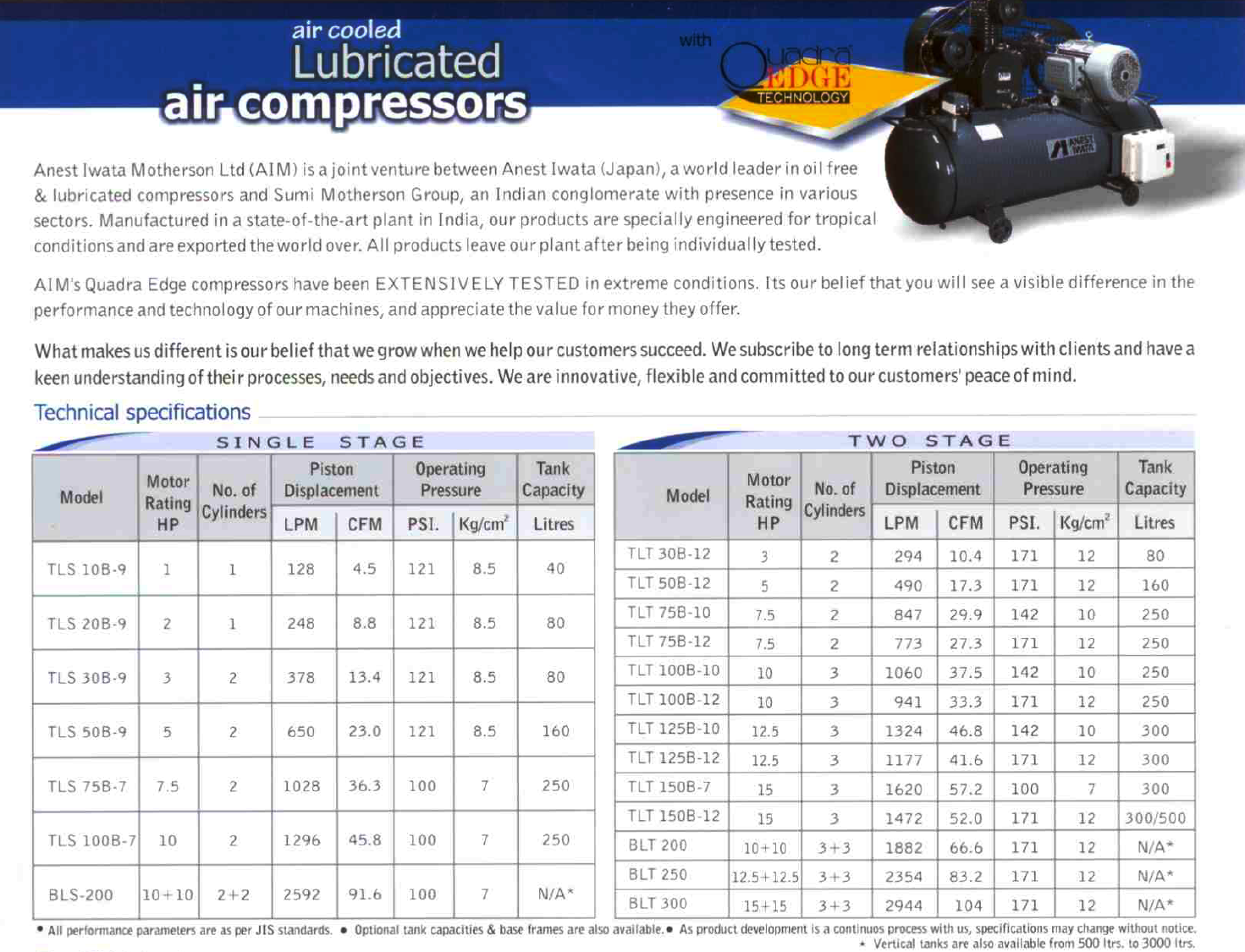

Unique feature & benefits of AIM lubricated air compressors

a.) New generation design.

Anest Iwata Japan has 75 years of experience in reciprocating compressor design, which includes the world’s first Composite Resin Oil Free compressor. AIM’s ‘Quadra Edge’ technology’s basic design principle was first developed in 1993 by Anest Iwata Japan, and was then tested extensively all around the world. Being a high performance-high durability design, it gives AIM’s compressors a performance edge over other compressors in the market, who have their design origins in the 1950’s ~ 1970’s.

b.) World Market Compressor

Our State of the art Factory – Anest Iwata Motherson (AIM) – has been established by the Sumi Motherson Group of India and Anest Iwata Japan to manufacture Lubricated Air Compressors. These are exported all over the world apart from being sold in the domestic Indian Market.

c.) Less Noise & Vibration & higher durability

Due to its crankshaft being supported at both ends, AIM compressors have visibly less Noise & Vibration levels when compared to other compressors in the market. Due to this, AIM compressors do not need any Grouting or Anti Vibration Pads when installed.

d.) Smaller Footprint

Our Japanese engineers have optimized the Air Receiver Sizes by improving on the durability of the compressors for increased start – stops. Due to this, AIM compressors save Expensive Industrial Space by using smaller Air Receivers as compared to Existing Compressors in the market.

e.) Lower Oil Carry Over & Higher Durability.

In Reciprocating Air compressors, the factor that determines the durability & life of a compressor is Oil Carry Over. AIM compressors have the following features over other compressors that result in lower Oil Carryover in running the compressors:

Features

- Bare compressor is assembled in Dust free environment.

- Cylinder has fine honing, done from special sticks imported from Japan

- AIM piston rings have a step cut design.

- The Breather System has a return pipe to the air intake filter.

Technical Benefits

- Lesser wear & tear of Piston ring & Cylinder.

- Surface roughness (Ra) of cylinder is 0.5 micron. Lesser wear & tear of Piston ring &cylinder.

- Blow – by is prevented, resulting in lower oil consumption.

- In case the filter chokes (due to low maintenance), this arrangement maintains vacuum in the crankcase, and prevents oil from being sucked into the compression system.

Commercial Benefits

- Life and durability of Compressor is increased.

- Life and durability of compressor is increased.

- Life and durability of compressor is increased.

- Lower carbonization of valve and valve plates, better long term performance.