The multi-tube shop-assembled Dustaclone from Thermax, consists of a housing containing a number of collection tubes, each of which is, in fact, a centrifugal dust collector. The dust laden gas entering the dirty air plenum moves downwards into the collecting tube (refer figure), being guided by a helical vaned annular ring. These vanes impart a smooth spiral movement to the gas, setting up a high centrifugal action.

As the gas descends in a cyclonic pattern, the dust is thrown outwards and is discharged through peripheral slots in a shave-off boot. A vortex is formed at the bottom of the centrifugal tube and the clean gas forms an inner whirl which ascends vertically into a discharge (outlet) tube, and then collectively out of the unit through the outlet plenum.

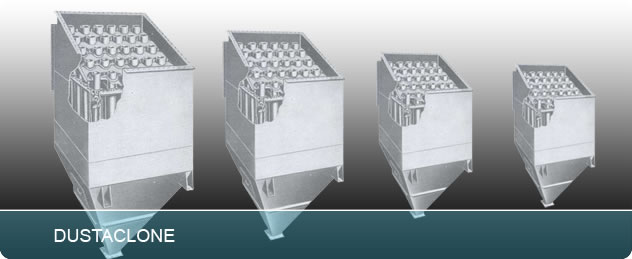

All the collectors are completely assembled to the extent practical for shipment, resulting in minimum erection man-hours and handling at the installation site.

Standard models in the Dustaclone-S range are now available:

- For gas volumes from 2,000 to more than 1,00,000 m3/hr

- With tubes varying in number from 2 to 100

Features & Benefits

- Centrifugally cast – uniform thickness. Even the slightest shift of 1/50 in core placement can cause a reduction in thickness by 3 mm, leading to tube failure in a shorter time due to wear and tear.

- Replaceable dust discharge boot – saves on replacement cost. Wear due to abrasion is maximum at the base of a collecting tube. A sturdy cast iron boltable boot at the base of the Dustaclone facilitates quick, economical replacement.

- Peripheral dust discharge – avoids dust re-entrainment.

- Integral mounting flange – effective sealing. There is an integral collar with lip and four holes for bolting.